The pharmaceutical industry continues to evolve, adopting new technologies and optimising resources to meet authentication and anticounterfeiting challenges.

One of the most effective solutions lies in pharmaceutical packaging enhanced with optical security technologies (OSTs) such as holograms, micro-lenses, colour-shifting effects, and diffractive devices.

There are proven examples both at the regulatory and individual brand levels.

These different strategies, at national and brand level, are further supported by continuous innovation from the authentication industry. Smart and instant authentication solutions now adopt a wide spectrum of OSTs:

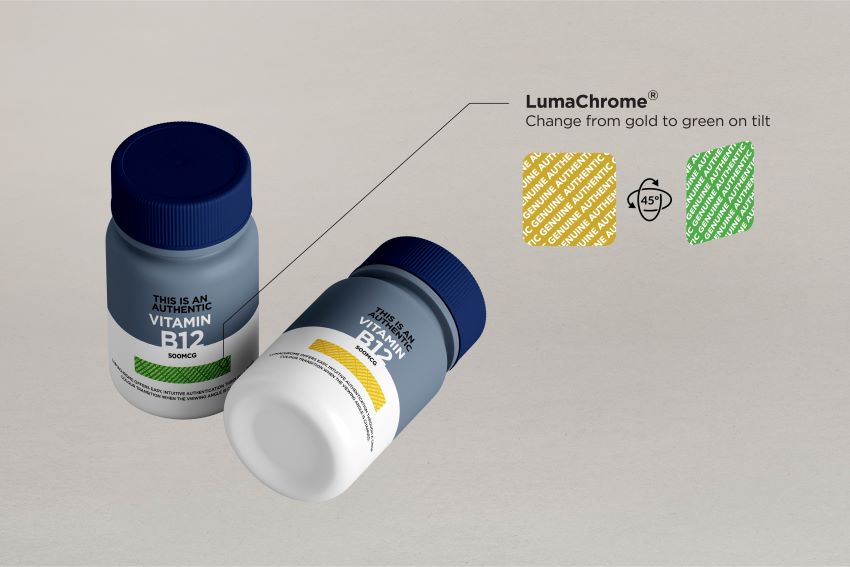

Authentix LumaChrome® – consists of optical thin film which changes from one distinctive colour to another when tilted.

Crane Authentication and MM Packaging are applying micro-optic technology, originally developed for banknotes, to pharmaceutical packaging, creating striking 3D effects.

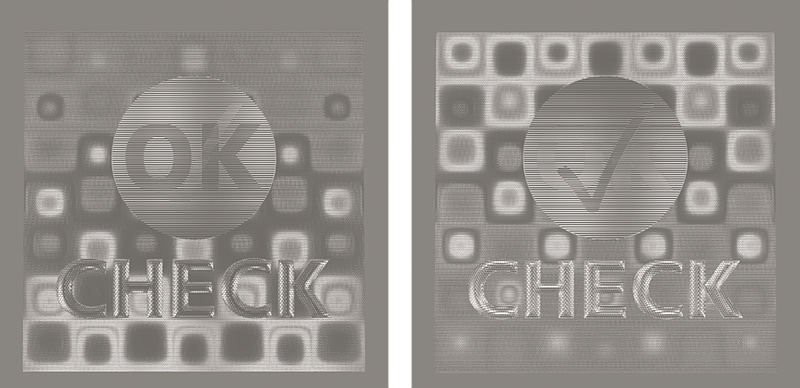

Giesecke+Devrient’s SIGN® technology embosses micro-optic features directly onto packaging, with more than one billion uses in the pharmaceutical sector.

KURZ’s TRUSTCOLOR® PLUS combines metallic colour-shifting with 3D spatial effects, creating visually striking and secure packaging.

.jpg)

Source: KURZ TRUSTCOLOR® PLUS.

SICPA QUAZAR® is a multifunctional security label with overt colours, secure 2D codes, tamper evidence, and covert forensic features. It can also link authentication data directly into ERP systems, strengthening oversight across manufacturing and distribution.

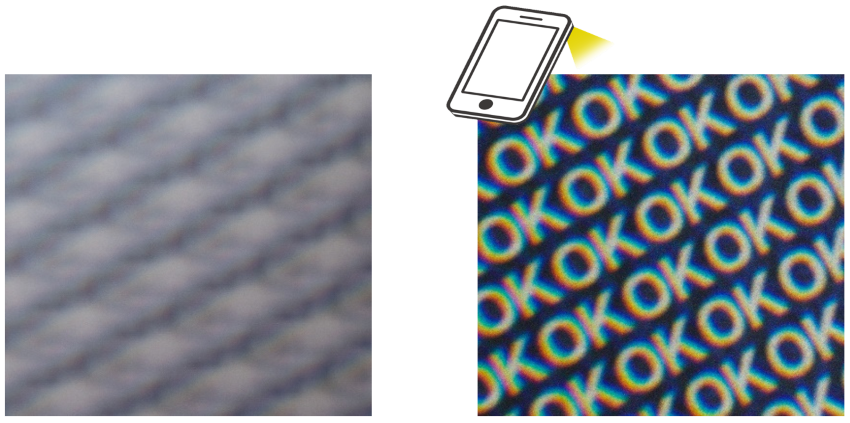

TOPPAN Illumigram™ (colour version) reveals 3D text like ‘GENUINE’ under a smartphone flashlight, engaging consumers in authentication.

As pharmaceutical production is increasingly outsourced, control and visibility become harder to maintain, and secure packaging becomes more important than ever. Integrating optical features solves these problems, as they can provide overt visual markers, tamper evidence, and covert identifiers that deter counterfeiting and support quick detection. In addition, the new generation OSTs can be customised to brand colour, enhancing aesthetic appeal and ensuring trust.

Some of these optical technologies now serve roles beyond authentication. Photonic crystal-based indicators, for example, track tampering and monitor time-temperature changes in cold-chain medicines – delivering multiple safeguards in a single label.

Optical security technologies are no longer just overt markers – they are evolving into multi-functional tools that combine authentication, compliance, supply chain security, and consumer engagement.

Integrated with digital identifiers, blockchain, and AI-driven systems, they provide pharmaceutical companies with a robust, adaptable defence against counterfeiting.